目录

使用耐弹性体 BRE 7231 (BRE7231) FKM 树脂的优点

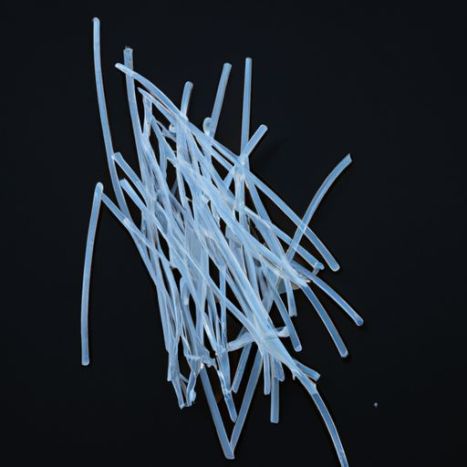

耐磨弹性体 BRE 7231 (BRE7231) FKM 树脂是一种高性能材料,具有卓越的耐磨性。这种弹性体由 3M Dyneon 开发,专门设计用于承受恶劣环境和苛刻的应用。在本文中,我们将探讨使用耐久弹性体 BRE 7231 (BRE7231) FKM 树脂的好处以及为什么它是许多行业的首选。

耐久弹性体 BRE 7231 (BRE7231) FKM 树脂的主要优势之一是其优越的耐磨性。这种材料具有很强的耐磨性,非常适合注重耐用性的应用。无论是暴露在刺激性化学品、极端温度还是高摩擦力下,这种弹性体都能承受最恶劣的条件,而不会影响其性能。

除了卓越的耐磨性外,耐磨弹性体 BRE 7231 (BRE7231) FKM 树脂还提供优异的耐化学性。该材料可耐受多种化学品,包括酸、碱、溶剂和油。这使其成为需要考虑暴露于腐蚀性物质的应用的多功能选择。借助耐磨弹性体 BRE 7231 (BRE7231) FKM 树脂,您可以相信,即使在最恶劣的环境中,您的设备也将受到保护且可靠。

Moreover, Resistant Elastomer BRE 7231 (BRE7231) FKM Resin is easy to process and can be customized to meet specific requirements. Whether you need a specific color, hardness, or texture, this material can be tailored to suit your needs. With its versatility and customization options, Resistant Elastomer BRE 7231 (BRE7231) FKM Resin offers endless possibilities for a wide range of applications.

In conclusion, Resistant Elastomer BRE 7231 (BRE7231) FKM Resin is a high-performance material that offers exceptional abrasion resistance, chemical resistance, temperature resistance, and mechanical properties. With its durability, reliability, and versatility, this elastomer is a preferred choice for many industries, including automotive, aerospace, and industrial applications. If you are looking for a material that can withstand the toughest conditions and deliver superior performance, Resistant Elastomer BRE 7231 (BRE7231) FKM Resin is the ideal choice for your next project.

Comparison of Abrasion Resistance of Resistant Elastomer BRE 7231 (BRE7231) FKM Resin and 3M Dyneon Base

Resistant Elastomer BRE 7231 (BRE7231) FKM Resin and 3M Dyneon Base are two popular materials known for their abrasion resistance properties. Abrasion resistance is a critical factor in many industries, as it determines the material’s ability to withstand wear and tear over time. In this article, we will compare the abrasion resistance of Resistant Elastomer BRE 7231 (BRE7231) FKM Resin and 3M Dyneon Base to help you make an informed decision when choosing a material for your application.

Resistant Elastomer BRE 7231 (BRE7231) FKM Resin is a fluorinated elastomer known for its excellent resistance to heat, Chemicals, and abrasion. It is commonly used in applications where high temperatures and harsh chemicals are present, such as in the automotive and aerospace industries. The abrasion resistance of BRE7231 FKM Resin is attributed to its unique molecular structure, which allows it to maintain its integrity even under extreme conditions.

On the other hand, 3M Dyneon Base is a fluoropolymer material that also offers excellent abrasion resistance. It is known for its low friction properties, making it ideal for applications where sliding or rubbing against other surfaces is common. The abrasion resistance of 3M Dyneon Base is achieved through a combination of its molecular structure and the addition of special additives that enhance its wear resistance.

When comparing the abrasion resistance of Resistant Elastomer BRE 7231 (BRE7231) FKM Resin and 3M Dyneon Base, it is important to consider the specific requirements of your application. While both materials offer excellent abrasion resistance, they may perform differently in different environments. For example, if your application involves exposure to high temperatures or harsh chemicals, Resistant Elastomer BRE 7231 (BRE7231) FKM Resin may be the better choice due to its superior heat and chemical resistance.

On the other hand, if your application requires low friction properties in addition to abrasion resistance, 3M Dyneon Base may be the more suitable option. Its low friction properties can help reduce wear and tear on moving parts, leading to longer-lasting performance.

In conclusion, both Resistant Elastomer BRE 7231 (BRE7231) FKM Resin and 3M Dyneon Base offer excellent abrasion resistance properties. The choice between the two materials will ultimately depend on the specific requirements of your application. Consider factors such as temperature, chemical exposure, and friction when making your decision. By choosing the right material for your application, you can ensure long-lasting performance and durability.