Table of Contents

Understanding the Specifications and Applications of API 5CT C95 Oil Well Tubing and Casing

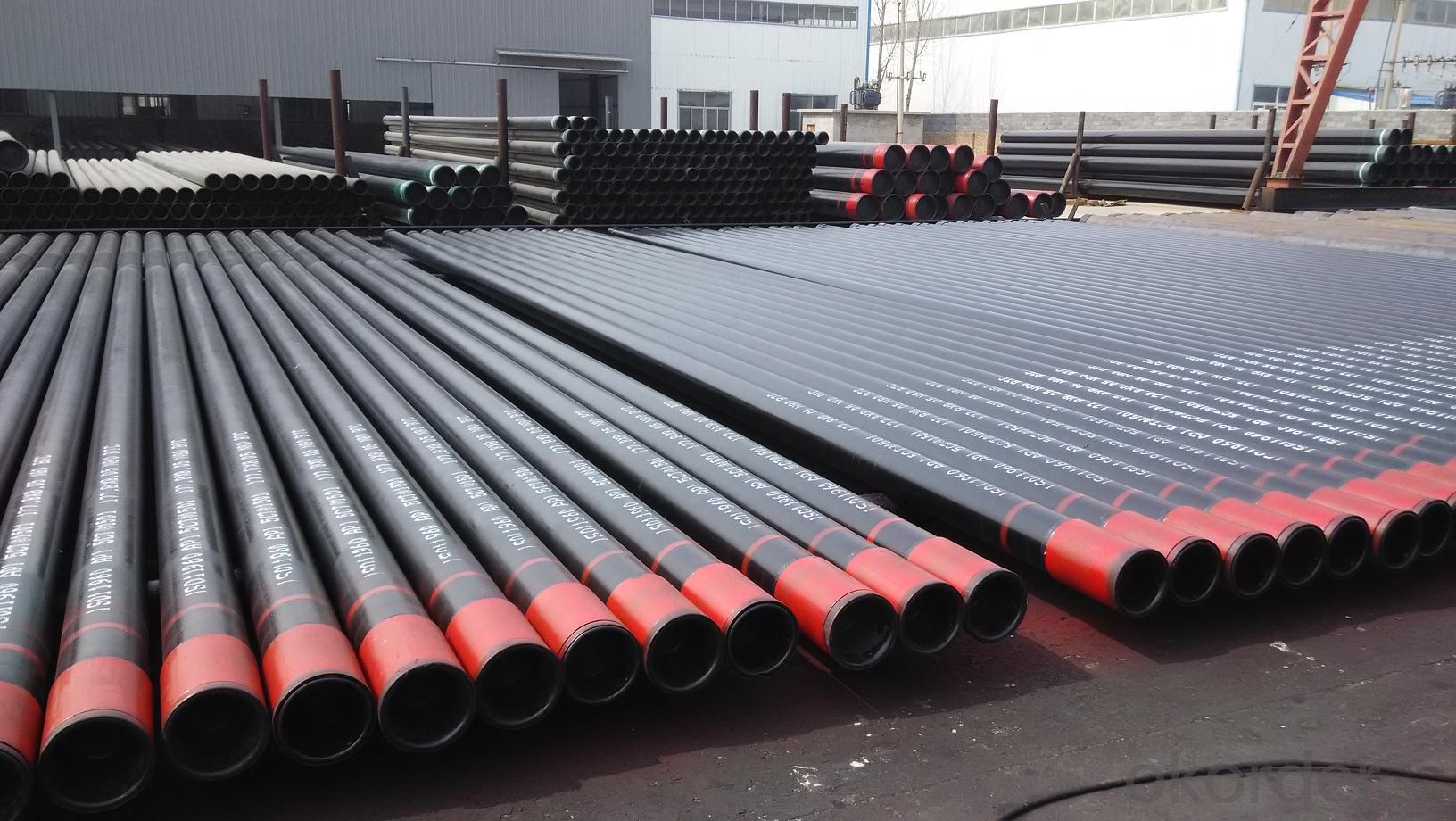

API 5CT C95 oil well tubing and casing play a vital role in the extraction and transportation of oil and gas from wells. These components undergo stringent specifications to ensure their durability and performance under various operating conditions. One critical aspect of these specifications is their resistance to hydrogen sulfide (H2S) corrosion, a common challenge in oil and gas production. In this article, we delve into the specifications and applications of API 5CT C95 oil well tubing and casing, with a specific focus on their anti-H2S properties and well casing protection.

API 5CT C95 tubing and casing are manufactured in accordance with the American Petroleum Institute (API) standards, which define the requirements for the design, manufacturing, and testing of oil country tubular goods (OCTG). These standards ensure consistency and reliability in the performance of tubing and casing across different wells and reservoir conditions. C95 grade is a medium Carbon Steel grade with higher strength compared to other lower grade materials, making it suitable for challenging environments encountered in oil and gas production.

One of the primary concerns in oil and gas production is the presence of hydrogen sulfide gas, which can cause corrosion of metal components, including tubing and casing. H2S corrosion can Lead to integrity issues, such as leaks and failures, jeopardizing the Safety and productivity of the well. Therefore, API 5CT C95 tubing and casing are designed to withstand H2S corrosion through specific alloying elements and heat treatment processes.

The anti-H2S properties of API 5CT C95 tubing and casing are achieved through alloying elements such as chromium (Cr) and Molybdenum (Mo), which enhance their corrosion resistance in sour environments. These alloying elements form protective Oxide layers on the surface of the steel, preventing direct contact with corrosive substances like H2S. Additionally, stringent heat treatment processes are applied during manufacturing to further improve the material’s resistance to corrosion and stress cracking.

In addition to their anti-H2S properties, API 5CT C95 tubing and casing also provide effective well casing protection against other corrosive agents and mechanical stresses. The casing serves as a barrier between the wellbore and the surrounding geological formations, preventing fluid migration and maintaining well integrity. Proper casing design and material selection are essential to ensure long-term performance and productivity of the well.

API 5CT C95 casing is designed with specific wall thickness and Thread configurations to withstand the pressures and loads encountered during drilling, completion, and production operations. The casing is installed and cemented in the wellbore to provide structural support and hydraulic isolation, minimizing the risk of leaks and formation damage. Additionally, corrosion inhibitors and coatings may be applied to the casing surface to provide an extra layer of protection against corrosive fluids and gases.

Furthermore, API 5CT C95 tubing is used for the conveyance of oil and gas from the reservoir to the surface. The tubing is installed inside the casing and is subjected to internal pressure, corrosive fluids, and mechanical loads during production. Therefore, it is essential to select tubing with appropriate material properties and dimensional specifications to ensure reliable performance and longevity in service.

https://www.youtube.com/watch?v=W7UwxDk5yUQIn conclusion, API 5CT C95 oil well tubing and casing are essential components in the oil and gas industry, providing critical functions such as reservoir access, fluid conveyance, and well casing protection. Their specifications and applications are carefully designed to withstand the challenges posed by corrosive environments, including hydrogen sulfide corrosion. By adhering to API standards and utilizing advanced materials and manufacturing processes, operators can ensure the integrity and reliability of their wells for safe and efficient production operations.

Exploring Anti-H2S T95 Well Casing Protection: Importance, Methods, and Best Practices

In the realm of oil well drilling and production, ensuring the integrity and longevity of well casing and tubing is paramount. One of the challenges faced in this industry is the presence of hydrogen sulfide (H2S) gas, which can corrode metal components, leading to equipment failure and safety hazards. In response to this challenge, the American Petroleum Institute (API) has developed standards such as API 5CT to regulate the materials and manufacturing processes of casing and tubing used in oil and gas wells. Among the various grades specified by API 5CT, C95 and T95 are particularly notable for their resistance to H2S corrosion.

C95 and T95 are high-strength carbon steels that have been specifically formulated to withstand the corrosive effects of H2S. This makes them ideal choices for well casing and tubing in environments where H2S is present, such as sour gas reservoirs. The designation “C95” indicates a yield strength of 95,000 psi, while “T95” denotes a yield strength of 95,000 psi with additional requirements for hardness and toughness. These properties make T95 well casing especially suitable for harsh operating conditions where both strength and resistance to corrosion are crucial.

Protecting T95 well casing from H2S corrosion involves employing various methods and best practices throughout the lifecycle of the well. One commonly utilized approach is the application of corrosion inhibitors, which are chemical compounds designed to mitigate the corrosive effects of H2S on metal surfaces. These inhibitors can be injected into the wellbore either continuously or intermittently to create a protective barrier that inhibits corrosion.

Another method of protecting T95 casing from H2S corrosion is the use of coatings or linings. These can include epoxy coatings, which provide a physical barrier between the metal surface and corrosive elements, or corrosion-resistant alloys that are applied as a cladding layer. These coatings and linings act as a sacrificial barrier, corroding in place of the underlying metal and extending the service life of the casing.

In addition to proactive measures, proper well design and operational practices also play a crucial role in protecting T95 casing from H2S corrosion. Wellbore fluids should be carefully monitored and controlled to minimize the presence of corrosive elements, and regular inspections and maintenance should be conducted to identify and address any signs of corrosion or degradation.

Overall, ensuring the integrity and longevity of T95 well casing in H2S environments requires a comprehensive approach that encompasses material selection, chemical treatments, coatings, and operational best practices. By implementing these measures, operators can minimize the risk of equipment failure, enhance safety, and optimize production efficiency in sour gas reservoirs. API 5CT C95 and T95 specifications provide a framework for achieving these objectives, offering guidance and standards to uphold the reliability and performance of oil and gas wells in challenging environments.